what graph to use when comparing control variables

Control Chart

Quality Glossary Definition: Control chart

Also called: Shewhart chart, statistical procedure control nautical chart

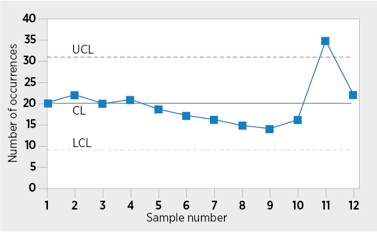

The command chart is a graph used to study how a process changes over fourth dimension. Data are plotted in fourth dimension order. A command chart ever has a fundamental line for the average, an upper line for the upper control limit, and a lower line for the lower command limit. These lines are determined from historical information. By comparison electric current information to these lines, you can draw conclusions about whether the process variation is consistent (in control) or is unpredictable (out of control, afflicted by special causes of variation). This versatile information collection and assay tool can be used past a variety of industries and is considered one of the seven basic quality tools.

Command charts for variable data are used in pairs. The top chart monitors the average, or the centering of the distribution of data from the procedure. The bottom nautical chart monitors the range, or the width of the distribution. If your data were shots in target practice, the average is where the shots are clustering, and the range is how tightly they are amassed. Control charts for attribute data are used singly.

- When to use a control nautical chart

- Bones procedure

- Create a control nautical chart

- Control chart resources

Control Chart Case

When to Utilise a Control Chart

- When decision-making ongoing processes by finding and correcting problems equally they occur

- When predicting the expected range of outcomes from a procedure

- When determining whether a process is stable (in statistical command)

- When analyzing patterns of process variation from special causes (not-routine events) or common causes (congenital into the process)

- When determining whether your quality improvement projection should aim to foreclose specific problems or to make central changes to the process

Basic Procedure

- Choose the appropriate control chart for your data.

- Determine the appropriate time flow for collecting and plotting data.

- Collect data, construct your chart and analyze the information.

- Look for "out-of-control signals" on the command chart. When 1 is identified, mark it on the chart and investigate the cause. Document how yous investigated, what you learned, the cause and how it was corrected.

Out-of-control signals

- A single betoken outside the control limits. In Figure 1, point 16 is in a higher place the UCL (upper command limit).

- Ii out of three successive points are on the same side of the centerline and farther than two σ from it. In Figure 1, point 4 sends that indicate.

- Iv out of 5 successive points are on the aforementioned side of the centerline and farther than 1 σ from it. In Figure 1, point 11 sends that betoken.

- A run of eight in a row are on the same side of the centerline. Or 10 out of eleven, 12 out of 14, or 16 out of 20. In Figure 1, bespeak 21 is eighth in a row above the centerline.

- Obvious consistent or persistent patterns that suggest something unusual about your data and your procedure.

Effigy 1 Command Chart: Out-of-Control Signals

- Proceed to plot information every bit they are generated. As each new data bespeak is plotted, check for new out-of-command signals.

- When you lot start a new command nautical chart, the process may be out of control. If so, the control limits calculated from the get-go twenty points are conditional limits. When y'all have at least 20 sequential points from a period when the process is operating in control, recalculate control limits.

Create a control chart

Meet a sample control chart and create your own with the control chart template (Excel).

Control Nautical chart Resource

Yous can likewise search articles, case studies, and publications for control nautical chart resources.

Books

The Quality Toolbox

Innovative Control Charting

Improving Healthcare With Command Charts

Example Studies

Using Control Charts In A Healthcare Setting (PDF) This teaching example written report features characters, hospitals, and healthcare data that are all fictional. Upon employ of the example study in classrooms or organizations, readers should exist able to create a command chart and interpret its results, and place situations that would be appropriate for command nautical chart analysis.

Quality Quandaries: Interpretation Of Signals From Runs Rules In Shewhart Command Charts (Quality Engineering) The case of Douwe Egberts, a Dutch tea and coffee manufacturer/distributor, demonstrates how run rules and a Shewhart control chart can be used as an effective statistical process control tool.

Manufactures

Spatial Control Charts For The Mean (Periodical of Quality Engineering science) The properties of this control nautical chart for the means of a spatial process are explored with false information and the method is illustrated with an example using ultrasonic technology to obtain nondestructive measurements of bottle thickness.

A Robust Standard Deviation Control Chart (Technometrics) Almost robust estimators in the literature are robust against either diffuse disturbances or localized disturbances only not both. The authors propose an intuitive algorithm that is robust confronting both types of disturbance and has better overall performance than existing estimators.

Videos

Control Chart

Excerpted from The Quality Toolbox , ASQ Quality Press.

Source: https://asq.org/quality-resources/control-chart

0 Response to "what graph to use when comparing control variables"

ارسال یک نظر